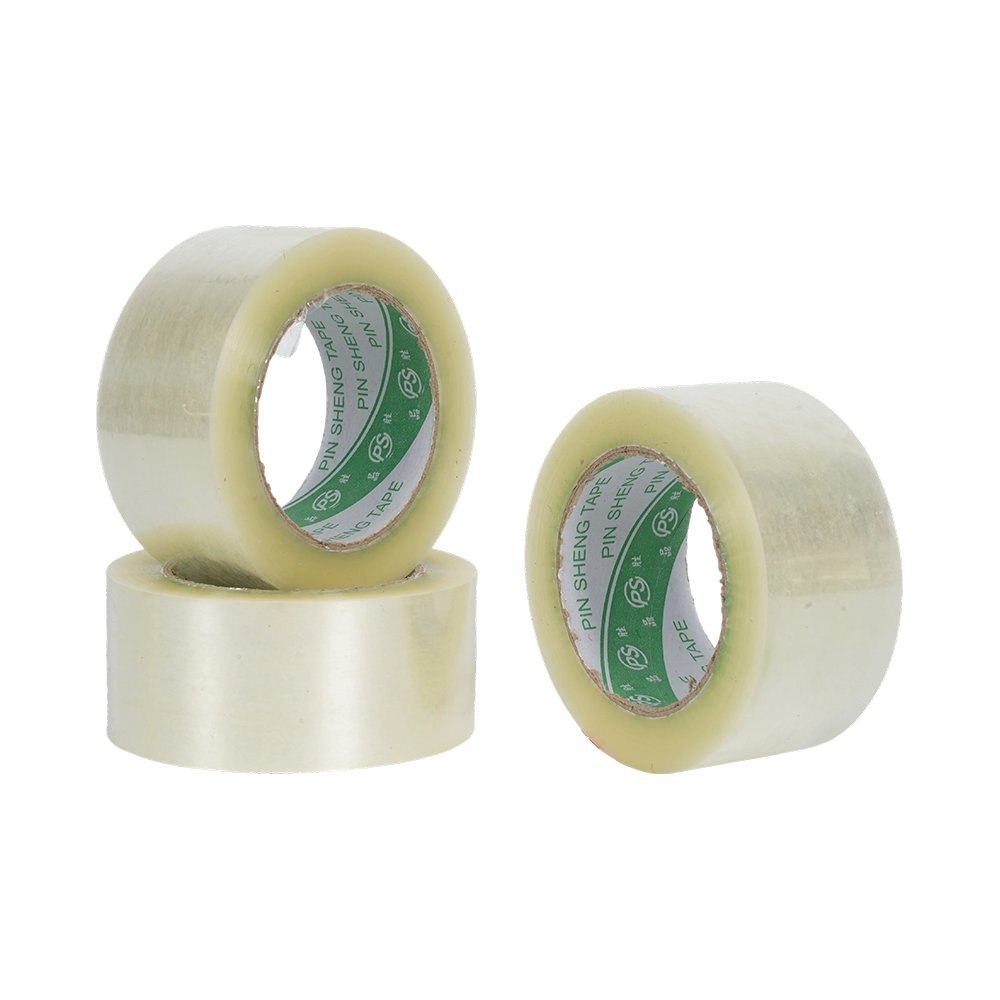

Packaging sealing tape is an industrial consumable made from BOPP film or kraft paper as the backing material, coated with a pressure-sensitive adhesive. It is primarily used for sealing various cartons, packaging, and temporary fixation of items. Its core function is to ensure packaging integrity through reliable adhesion, improving logistics and transportation efficiency, and meeting daily sealing and pasting needs. The product offers balanced initial tack and holding power, adapting to different environments and surfaces, serving as a fundamental and essential auxiliary material in warehousing, logistics, and general office applications.

Core Advantages:

Cost-Effective: Low unit cost of use, suitable for large-scale packaging operations.

Easy Application: Ready-to-use; simply peel and apply without additional tools or activation.

Broad Compatibility: Adheres effectively to most common packaging surfaces (e.g., corrugated cardboard, certain plastics).

Multiple Specifications: Available in various widths, lengths, and thicknesses to match different carton sizes and load-bearing requirements.

Product Features:

Backing Material: Commonly biaxially oriented polypropylene (BOPP) film, known for high tensile strength and clarity; also available in kraft paper backing, which is writable and easy to tear.

Adhesive: Utilizes pressure-sensitive acrylic or rubber-based adhesives, providing a balance of initial tack and shear resistance.

Dimensions: Common widths include 48mm, 50mm, 60mm, etc., supplied in rolls measured in yards or meters.

Performance Parameters: Includes thickness (micron-level), breaking strength, peel adhesion, conforming to general industrial packaging standards.

Application Scenarios:

Logistics & Shipping: Sealing corrugated boxes to prevent opening during transit.

Warehouse Management: Sealing product packages, reinforcing cartons.

Office & Household Use: Sealing document envelopes, temporary fixation and pasting of lightweight items.

Manufacturing Processes: Temporary positioning and fixation of components during product assembly.

Usage & Storage Notes:

Surface Preparation: Ensure the application surface is dry, free from oil and dust for optimal adhesion.

Ambient Temperature: Recommended application temperature is between 10°C and 35°C. Lower temperatures may reduce adhesive performance.

Storage Conditions: Store in a cool, dry place away from direct sunlight or heat sources to prevent aging, adhesive oozing, or backing deformation.

Safe Handling: Use a compatible tape dispenser for efficient and safe application; avoid rapid manual tearing to prevent cuts.

English

English