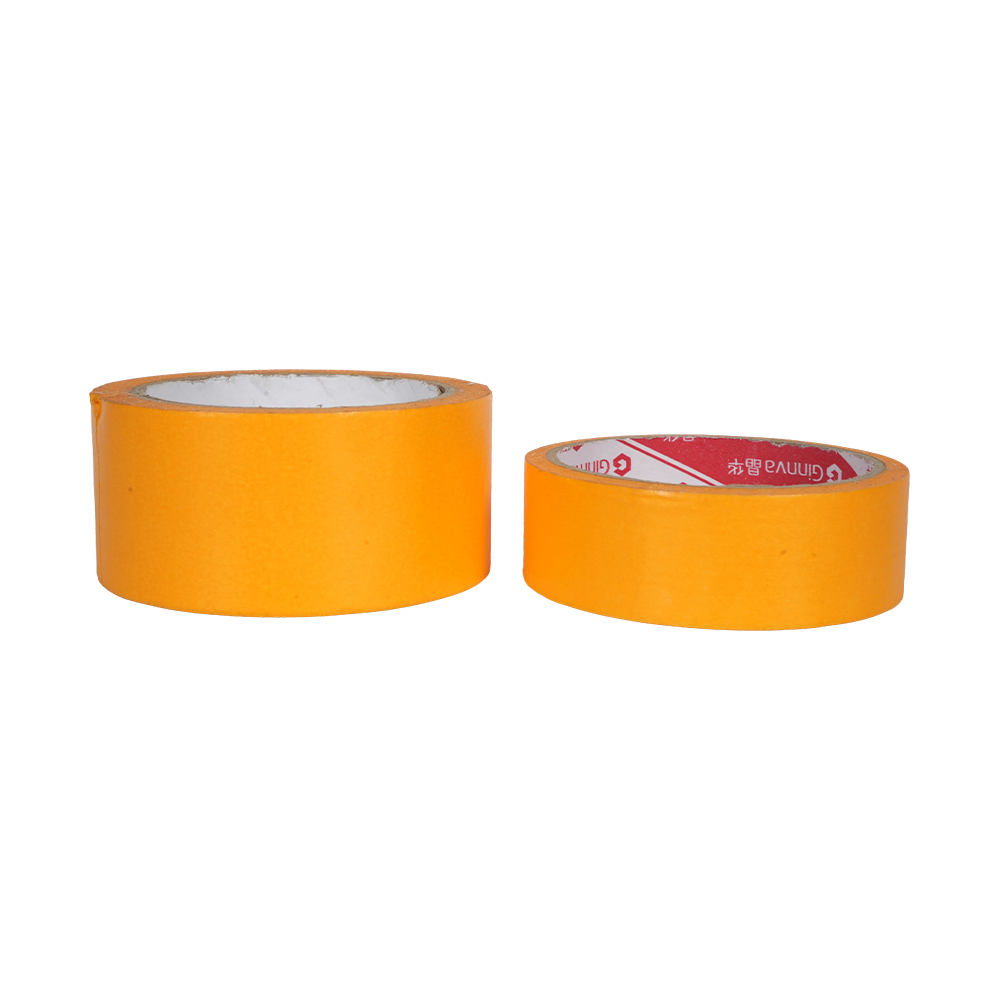

This product is a high-temperature resistant masking tape, also known as crepe paper tape. It is manufactured using specially treated crepe paper as the backing, coated with an acrylic adhesive. Through process adjustments, the tape offers varying temperature resistance grades to suit different high-temperature working environments. The standard thickness is 0.14mm, and the width can be custom-produced within the range of 5mm to 500mm to meet diverse industrial sizing requirements. This tape is designed to deliver sharp paint lines and minimize adhesive residue upon removal in applications such as precision spraying, electronic component protection, and high-temperature baking processes.

Core Advantages

Adjustable Temperature Resistance: Offers different grades of high-temperature resistance based on processing, suitable for environments from room temperature to specific high temperatures.

Customizable Sizes: Width can be produced from 5mm to 500mm according to customer requirements, providing flexibility for various masking areas and shapes.

Optimized Backing & Adhesive: Crepe paper backing provides good flexibility, tensile strength, and easy tear-off. Acrylic adhesive offers consistent adhesion and weather resistance.

Product Specifications

Backing Material: Specially treated crepe paper, featuring good toughness, tear resistance, and conformity to curved surfaces.

Adhesive: Acrylic pressure-sensitive adhesive, providing balanced initial tack and holding power, with solvent and aging resistance.

Thickness: Standard thickness is 0.14mm, balancing masking bulk and handling.

Temperature Resistance: Depending on the specific model, can withstand elevated temperatures for a defined period (e.g., within the range of 80°C to 180°C, refer to product datasheet for exact specifications).

Color: Typically, natural crepe paper color (off-white/light yellow) for clear demarcation lines.

Release Force: Designed for easy hand-tearing and features moderate unwind force for convenient on-site application.

Application Scenarios

Spraying & Surface Treatment: Masking for paint and powder coating on automotive parts, furniture, and metal workpieces, enabling precise color separation and protection.

Electronics & Electrical Industry: Protection of solder points and component masking during PCB wave soldering and reflow soldering.

High-Temperature Processes: Temporary protection of non-treatment areas during powder curing, baking, or heat treatment.

General Industrial Bundling & Fixing: Suitable for temporary positioning, identification, or light-duty fastening where temperature resistance is required.

FAQ & Solutions

Q1: Adhesive residue remains on the surface after tape removal?

A: This may be related to substrate surface energy, cleanliness, or prolonged tape dwell time. Ensure the surface is clean, dry, and free of oil before application. For sensitive surfaces, consider selecting a tape with a more compatible adhesive type or removing the tape promptly after the process.

Q2: Tape edges lift, or the tape detaches in high-temperature environments?

A: Verify that the maximum temperature resistance of the tape used matches or exceeds the actual operating temperature. Select a model with a temperature rating higher than the actual condition and apply sufficient pressure during installation to ensure full contact between the tape and the surface.

Q3: Is tape difficult to apply smoothly on curved surfaces?

A: The crepe paper backing inherently offers some stretch and flexibility. Apply the tape in sections, stretching it slightly and smoothing it down by hand to reduce wrinkles and air bubbles.

English

English