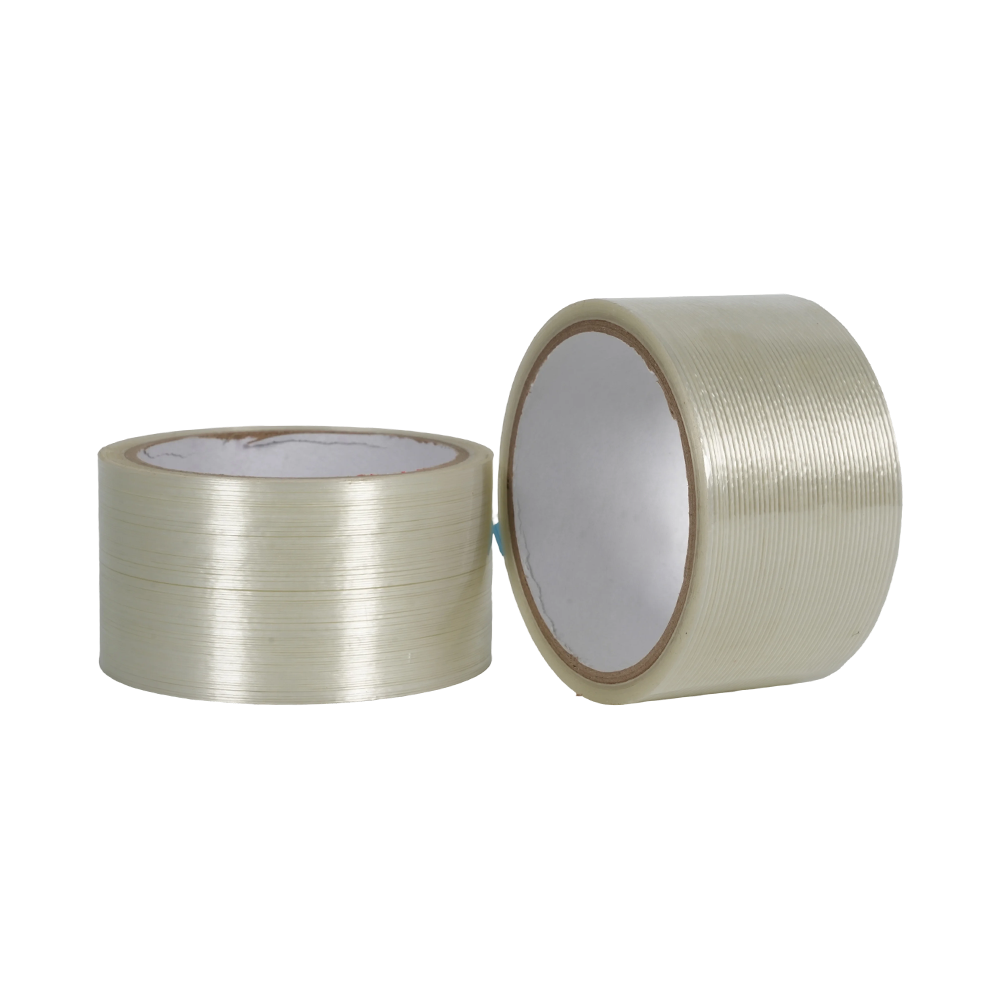

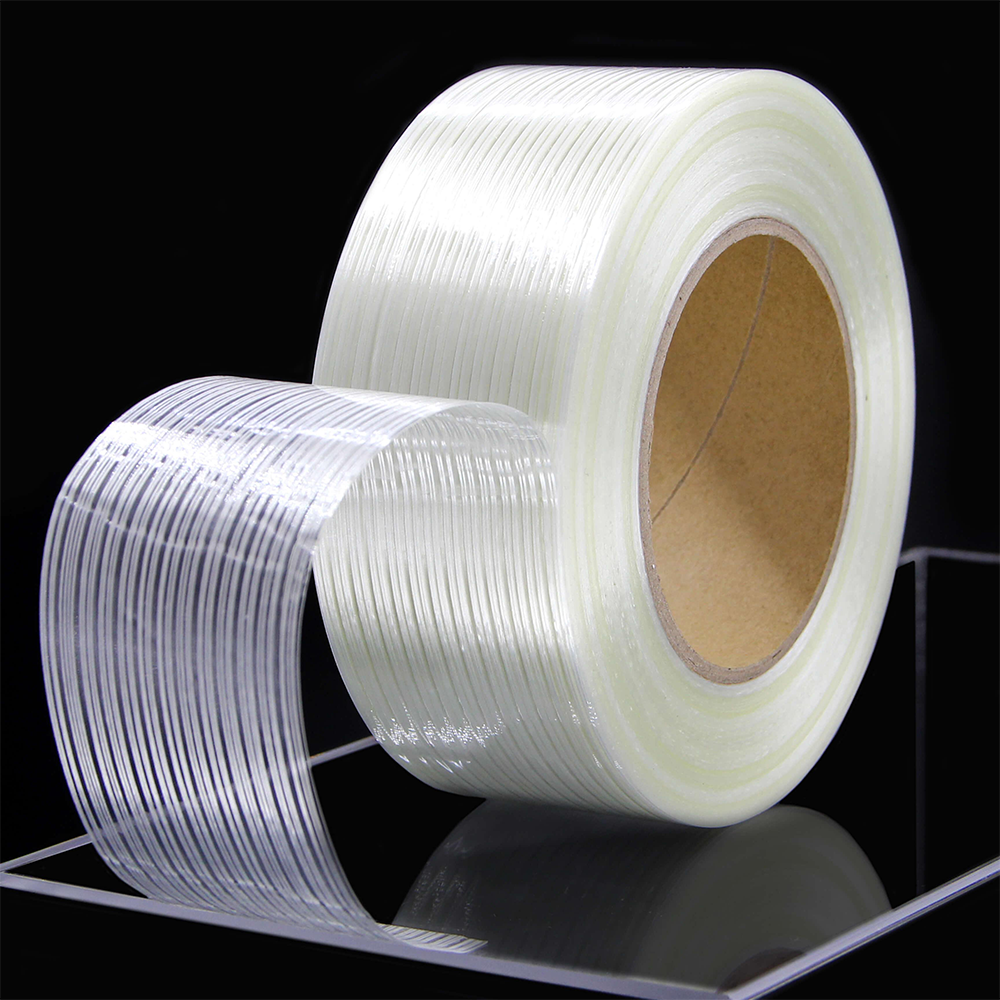

Low-Residue Fiberglass Tape is an industrial tape composed of a fiberglass cloth backing coated with a specific pressure-sensitive adhesive. Its core function is to provide strong adhesion while minimizing adhesive transfer and residue upon removal from substrates. This tape demonstrates compatible adhesion to a wide range of materials, including both high surface energy materials (e.g., metals, glass) and some low surface energy materials (e.g., certain plastics). It is primarily applied in applications such as fixing, insulating, bundling, and protection during the manufacturing processes of household appliances, offering practical value in enhancing production efficiency and maintaining end-product cleanliness.

Key Advantages:

Low Residue Upon Removal: Special adhesive formulation reduces glue transfer on most surfaces after peeling, facilitating cleaner maintenance.

Broad Material Compatibility: Adheres effectively to both high and low surface energy materials, potentially reducing tape inventory variety on production lines.

High Strength & Dimensional Stability: The fiberglass backing provides good tensile strength, puncture and tear resistance, with temperature resistance and minimal elongation.

Product Features:

1. Backing: High-strength fiberglass cloth.

2. Adhesive: Low-residue acrylic pressure-sensitive adhesive.

3. Adhesion Performance: Offers reliable initial tack and holding power on various substrates like stainless steel, aluminum alloy, PC, and ABS.

4. Physical Properties: Features good temperature resistance, flame retardancy (subject to specific grade), and electrical insulation.

5. Standard Color: White.

Application Scenarios:

Household Appliance Manufacturing: Wire harness bundling, temporary PCB positioning, fixing of insulation materials, and temporary masking or protection during assembly of housing components.

Electronics & Electrical: Medium-strength insulation and fixing.

Industrial Assembly: Temporary holding, masking, or labeling applications where subsequent removal with minimal residue is required.

Usage & Storage Notes:

For optimal adhesion, ensure application surfaces are clean, dry, and free from oil or contaminants.

Store in a cool, dry place away from direct sunlight, high temperatures, and humidity. Recommended storage temperature is between 15°C and 30°C.

Conduct adhesion tests on specific materials and under actual conditions to confirm suitability before full-scale application.

English

English