Zhejiang Geruite Packaging Materials Co., Ltd. is located in Zhejiang Province, a region renowned for its developed manufacturing industry and vibrant economy, has been dedicated to the in-depth cultivation and innovation of packaging materials since its establishment. With its superior product quality and professional services, the company has become a leading supplier of packaging solutions in the region, establishing a strong reputation in the industry.

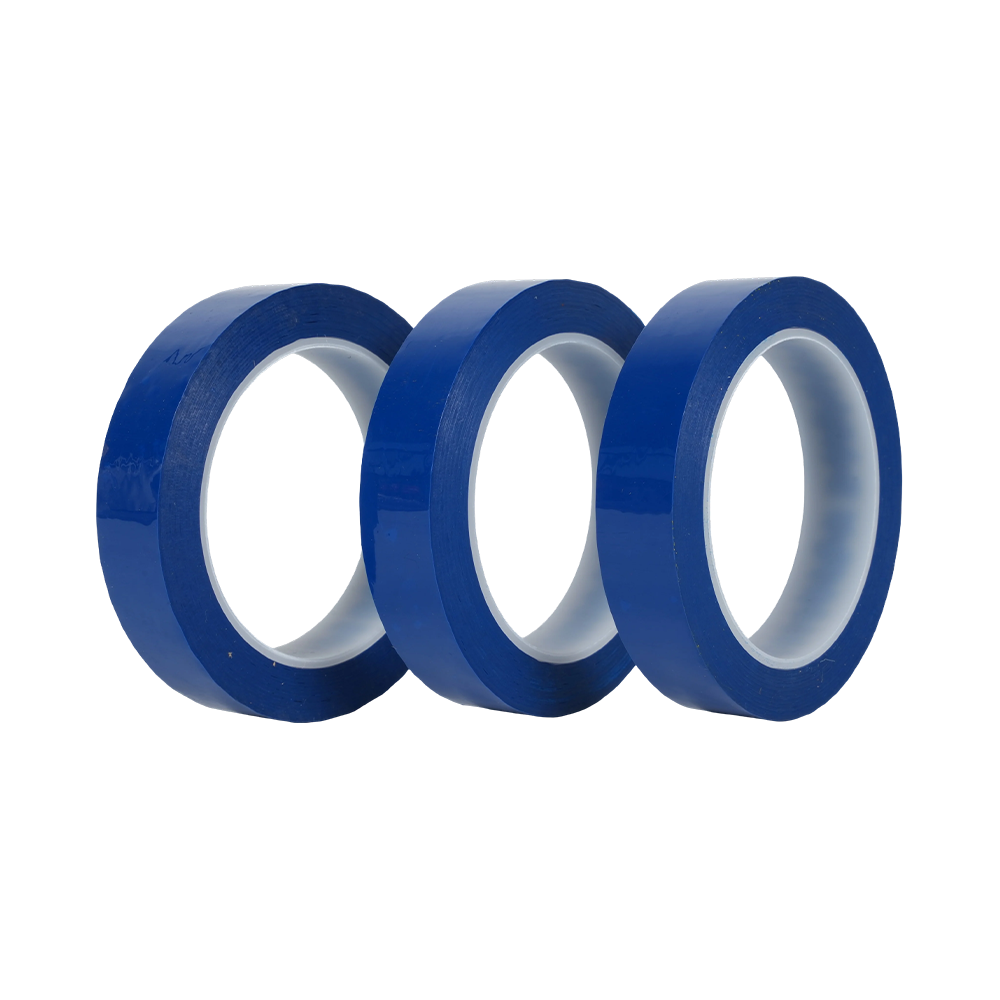

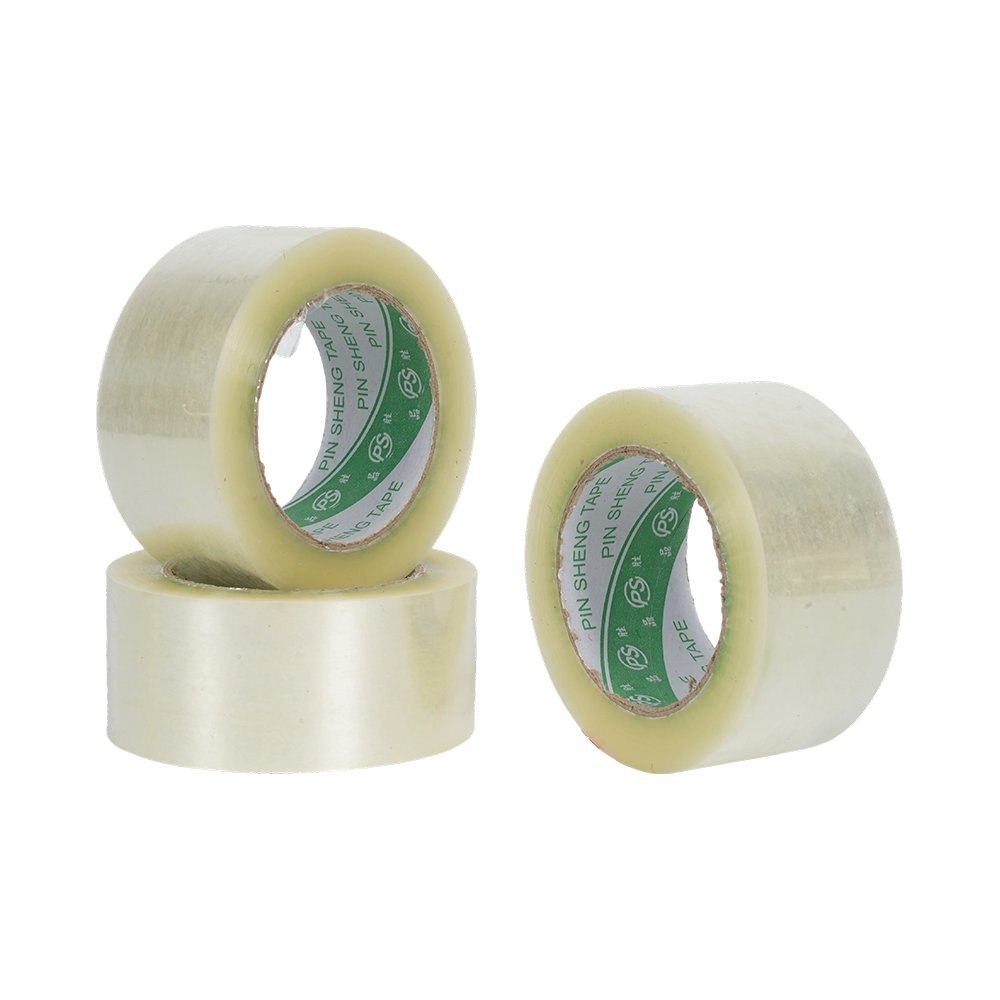

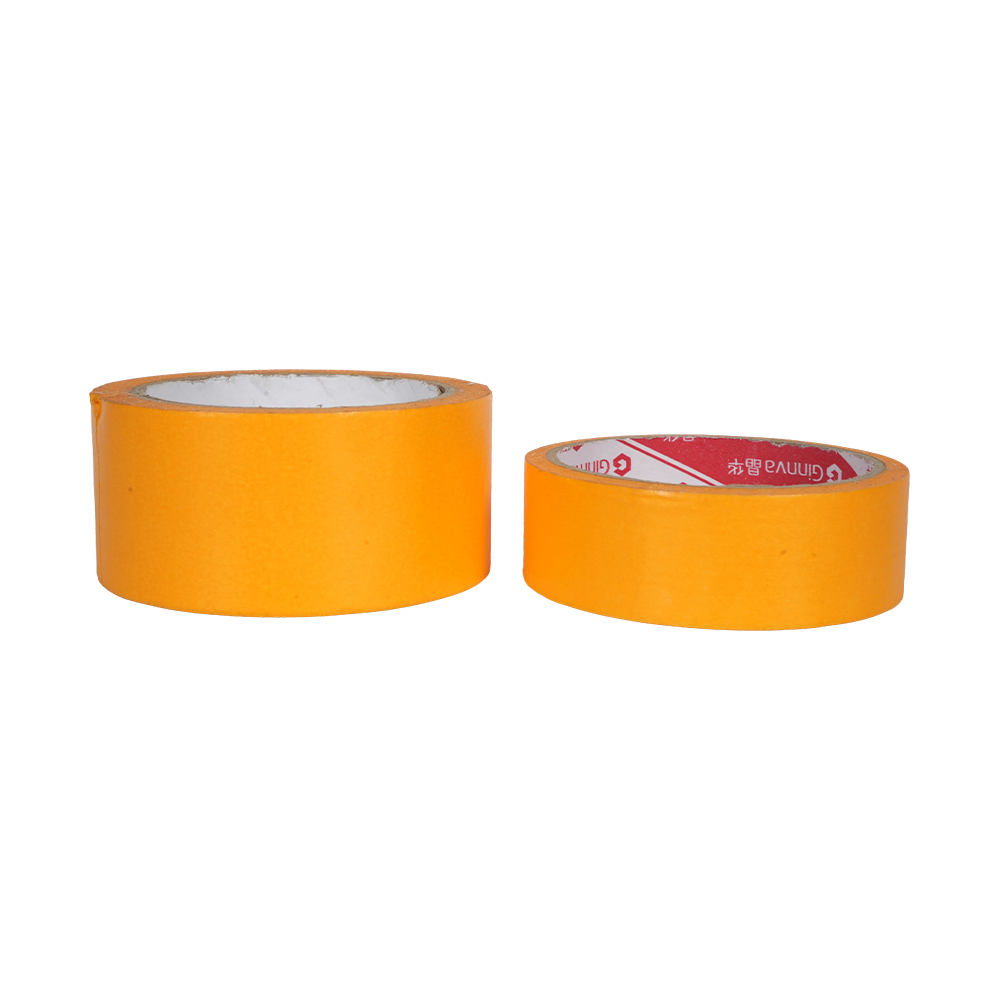

The company's core business encompasses the research, development, production, and sales of various high-performance tapes and packaging materials. Its main product lines are diverse, including BOPP tapes and kraft paper tapes widely used for everyday sealing and securing; masking tapes suitable for inkjet printing, electronics, electrical engineering, and special processes; high-temperature resistant tapes and metal tapes designed for extreme environments; and PE stretch film, PP strapping, and high-strength PET strapping for unitized cargo stabilization and protection, and improved logistics efficiency. These products serve a wide range of industries, including logistics and express delivery, household goods, electronics, construction and decoration, and industrial manufacturing, providing customers with safe, reliable, and efficient packaging options.

We firmly believe that quality is the lifeline of a company. Equipped with advanced production equipment and a rigorous quality control system, the company meticulously refines every step from raw material procurement to the production process, ensuring stable product performance and meeting diverse customer needs. Currently, the company's annual output value has reached over 60 million RMB. This figure not only reflects our production scale and market recognition but also motivates us to continuously move forward.

Looking to the future, Zhejiang Geruite Packaging Materials Co., Ltd. will continue to uphold the spirit of "enterprising spirit and craftsmanship," increasing investment in technological research and development, optimizing product structure, and improving service levels. We are committed to becoming the most trusted packaging material partner for our customers, contributing more to industry progress and customer success.

English

English